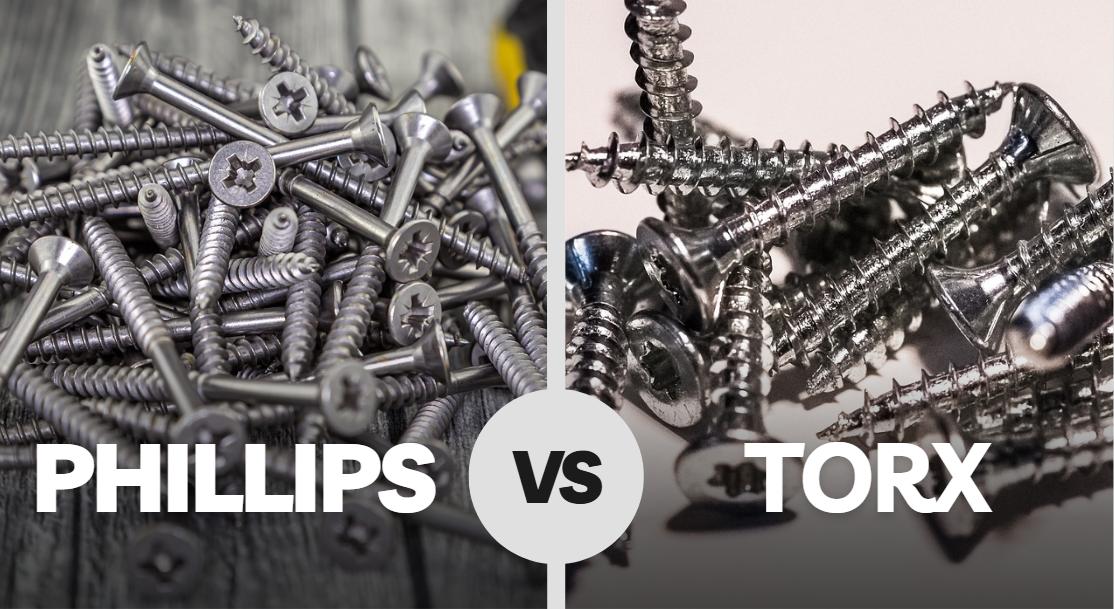

Torx and Phillips are common screw types. They are widely used in modern machinery and electronics. These screw variations possess unique characteristics that set them apart. This comprehensive Torx vs Phillips screw guide explores their differences. The aim is to help you understand which screw type and screwdriver you need.

Philips Screws: A Detailed Overview

This screw type is named after Henry F. Phillips. It revolutionized industrial assembly processes in the mid-20th century. Its distinctive design quickly became a standard in manufacturing. It offers engineers and manufacturers a reliable fastening solution.

Shape

Philips screws feature a cross-shaped recess with rounded corners. This allows screwdrivers to easily engage and rotate. The design enables smooth insertion and moderate torque application.

Pros

- Affordable and widely available

- Easy to manufacture

- Compatible with automated assembly processes

- Standardized across multiple industries

Cons

- Tendency to cam out under high torque

- Higher likelihood of stripping with excessive force

Uses

Philips screws are more common overall. They are used in consumer electronics, automotive components, and general mechanical assemblies. They have wide applications. Some of the common ones include:

- Computer hardware

- Household appliances

- Automotive dashboards

- Consumer product manufacturing

Related Tools

The standard Phillips head screwdriver is the primary choice. This tool is ideal for installation and removal of these screws. It’s characterized by its cross-shaped tip matching the screw’s recess. These screwdrivers are typically color-coded. They are sized numerically.

Torx Screws: A Detailed Overview

Torx screws are a more advanced fastening solution. They are designed to address limitations found in traditional screw designs. This screw type was developed by Camcar Textron in 1967. It offers enhanced performance and precision across various technical applications.

Shape

These screws feature a six-pointed star-shaped recess. They provide superior torque transmission and reduced slippage.

Pros

- Reduced stripping potential

- Higher torque transmission capability

- Better load distribution

Cons

- More expensive than traditional screws

- Requires specialized screwdrivers

- Less universally available

- More complex manufacturing process

Uses

Torx screws are prevalent in high-precision industries. These include sectors that require robust mechanical interfaces. The key uses/applications include:

- Computer hardware

- Aerospace components

- Medical equipment

- High-performance automotive systems

Related Tools

The specialized Torx head screwdriver is the primary choice. Its six-pointed tips precisely match the Torx screw’s geometry to ensure optimal performance. These precision tools are available in various sizes. This typically ranges from T1 to T100. The wide range allows for compatibility with different screw dimensions and applications.

Torx vs Phillips: The Comparison Chart

Understanding the nuanced Torx vs Phillips screw differences helps select the most appropriate fastening solution. This comparison chart reveals distinct advantages and limitations for each design:

| Characteristic | Philips Screws | Torx Screws |

| Shape | Cross-shaped recess with rounded corners | Six-pointed star-shaped recess |

| Torque Handling | Tends to cam out under high torque | Superior torque transmission |

| Manufacturing Cost | Lower cost | Higher cost |

| Stripping Resistance | More prone to stripping | Reduced stripping potential |

| Common Uses | Consumer electronics, general assemblies | Precision industries, high-performance systems |

| Required Tool | Phillips screwdriver, sometimes flat head screwdriver | Torx screwdriver |

| Precision Level | Moderate | High |

| Industry Prevalence | Widely used | Growing adoption |

Product Highlight: Jakemy JM-8176

Versatility in tool selection can dramatically improve maintenance and repair efficiency. Having a screwdriver capable of handling multiple screw types, e.g., Torx vs Phillips, is a significant advantage. Our JM-8176 is a key example of this. It’s a comprehensive screwdriver set designed to meet diverse technical requirements. It’s a meticulously engineered solution for complex repair and maintenance tasks. The following features make it one of the best precision screwdriver sets for professionals and enthusiasts alike:

- 106-piece comprehensive set supporting multiple screw types, including Hex, Torx, Phillips, Slotted, etc.

- CR-V chrome-vanadium steel bits with exceptional durability

- Nickel-plated surface enhancing corrosion resistance

- Includes specialized bits for precision electronics repair

- Compact design enabling portable usage

- Comprehensive accessory collection covering numerous applications

Conclusion

Overall, the Torx vs Phillips screw choice depends on specific application requirements, torque needs, and precision expectations. While both designs offer unique advantages, understanding their characteristics enables more informed decision-making. At Jakemy, we are committed to providing reliable, high-quality tools that empower professionals and DIY users. Our JM-8176 set exemplifies our dedication to innovation and functionality.