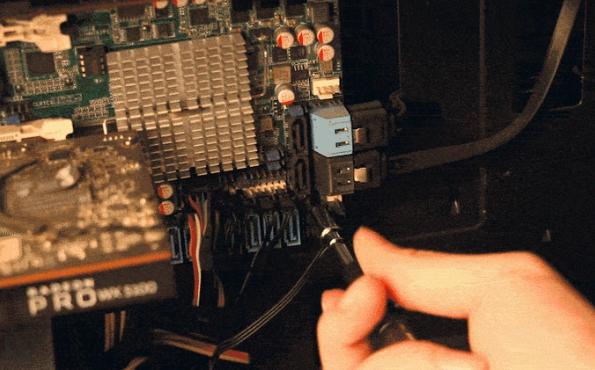

Picture this: You’re straining to tighten screws in a cramped, awkward spot. Every twist of the screwdriver forces you to pause, readjust your grip, and reposition the tool. What should take minutes drags into a futile cycle of effort—and worse, each slip of misalignment leaves behind jagged scratches.

A solution to such problems is a ratcheting screwdriver. This article explores what a ratcheting screwdriver is, how it works, and more. Read on!

What Is A Ratcheting Screwdriver?

A ratcheting screwdriver streamlines the process of tightening or loosening screws. This is achieved by eliminating the need to constantly lift and reposition the tool after each turn. The core of ratcheting screwdrivers is a ratcheting mechanism, a gear and pawl system.

How Does A Ratchet Screwdriver Work?

When you turn the ratcheting screwdriver handle in a selected direction (to either tighten or loosen screws), the pawl locks into the teeth of the gear. It then transfers rotational force to screwdriver bits. When you reverse the handle’s motion, the pawl slides over the gear teeth and the ratcheting mechanism is disengaged. Thus the handle can spin freely while maintaining contact with the screw.

How to Use a Ratcheting Screwdriver

Using a ratcheting screwdriver is straightforward, but following these steps ensures optimal performance:

1. Select the Correct Screwdriver Bit

Choose the right screwdriver bit that matches your screw’s head type and size. A ratchet screwdriver set offers a variety of bit types (e.g., Phillips, flathead, Torx) in different sizes.

2. Insert the Bit

Secure the bit into the screwdriver’s magnetic or quick-release chuck.

3. Set the Direction

Adjust the directional switch to “tighten” or “loosen”.

4. Engage the Screw

Align the bit with the screw head and apply gentle downward pressure to prevent slipping. Rotate the handle in short, back-and-forth motions. The ratchet mechanism will drive the screw with each forward stroke while free-spinning on the return.

5. Switch Directions as Needed

Flip the directional switch to reverse the action when removing screws or adjusting torque.

Ratchet vs Non-Ratchet Screwdriver

The following chart highlights the differences between ratchet and traditional non-ratchet screwdrivers:

| Ratchet Screwdriver | Non-Ratchet Screwdriver | |

| Mechanism | Features a gear-and-pawl system, eliminating the need to reposition grips | Has a traditional fixed design requiring full repositioning after each turn |

| Effort | Require less effort, especially in tight or confined spaces | Demanding due to the constant need for repositioning |

| Size | Bulkier due to a more complex design | Generally smaller and lighter |

| Use Cases | Best for projects with limited wrist movement | Used for various screw-driving tasks |

You can also click here for a more dedicated explanation of ratchet vs non-ratchet differences.

Which Ratchet Screwdriver Set to Choose

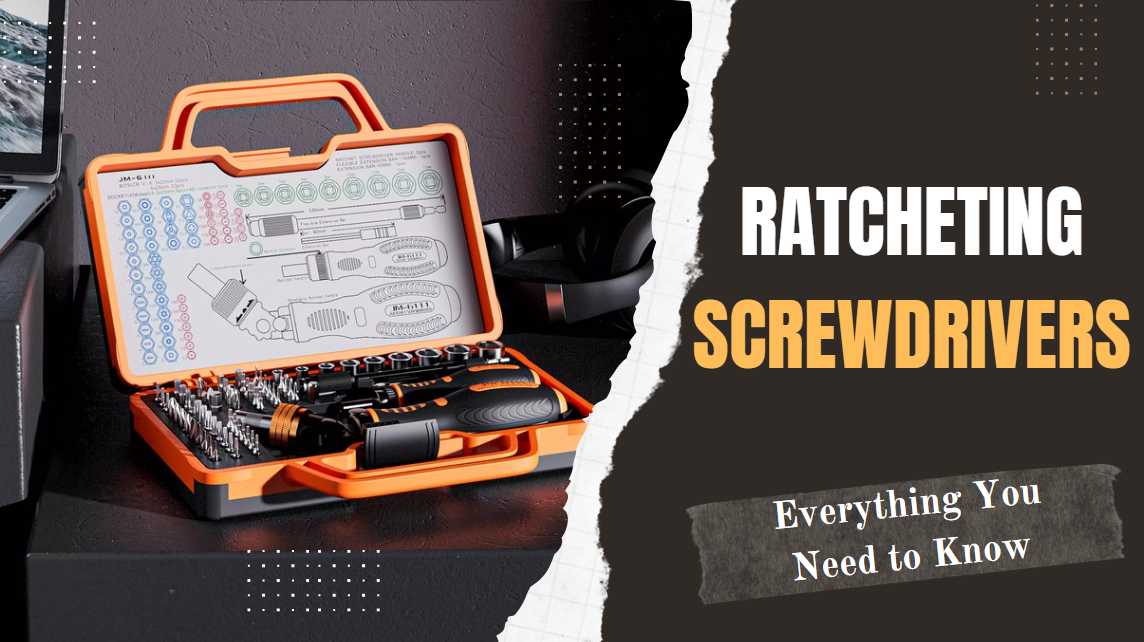

Jakemy is a trusted screwdriver manufacturer. At Jakemy, we provide high-quality, reliable screwdrivers and screwdriver sets. One of our best ratcheting screwdrivers JM-6111 showcases our commitment to quality. It is a versatile screwdriver tool kit. The key features of this multi bit ratchet screwdriver include:

- 69 in 1 ratchet screwdriver tool kit with various head type and bit sizes and 2 non-slip handles

- The bigger handle can be adjusted 180°degrees

- Both handles are made of CR-V high-grade materials

- Features a twist reverse and ratchet lock mechanism to reduce effort and fatigue

- A portable box made of TPR material for easy transportation

- Commonlyused in automotive parts, home appliances, DIY projects, etc.

Conclusion

Overall, a ratcheting screwdriver is an essential tool for efficient and precise screw-driving tasks. Its ratcheting mechanism allows for time-saving and effortless rotation. At Jakemy, our ratcheting screwdriver set JM-6111 is a popular choice among DIY enthusiasts and professional mechanics. Browse our website to learn more about our ratcheting screwdrivers and other quality products.