Jakemy Screwdriver Services

Screwdriver Wholesale & Supply

What we can offer:

- Free Logo Custom Service

- High-quality Raw Materials

- Quick Sample Custom Service

- Quick Delivery(In-stock items ship within 7 business days)

- Quality Control

- Lower MOQ

- 24/7 Customer Support

Screwdriver OEM & ODM

What we can offer:

- Stylish & Unique Design

- Competitive pricing

- 60 Day Warehousing Service

- Quick Delivery (Normally 7-20 work days)

- 1 V 1 Technical Support

- Global Branding Experience

Top Screwdriver Manufacturer in China – Jakemy

Join us on a virtual tour of our factory

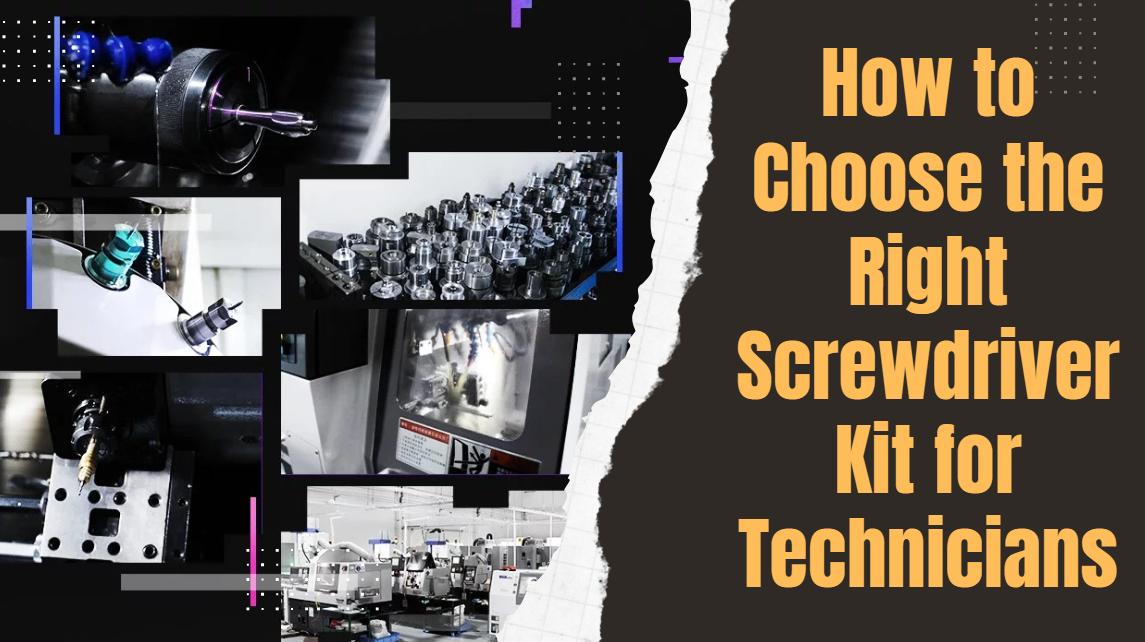

Established in 1998, Jakemy has been an experienced screwdriver manufacturer & supplier in China. Covering an area of 6,000 square meters of factory, we boast 6 production lines and 20 high-precision Taiwan equipment to ensure good quality and quick delivery.

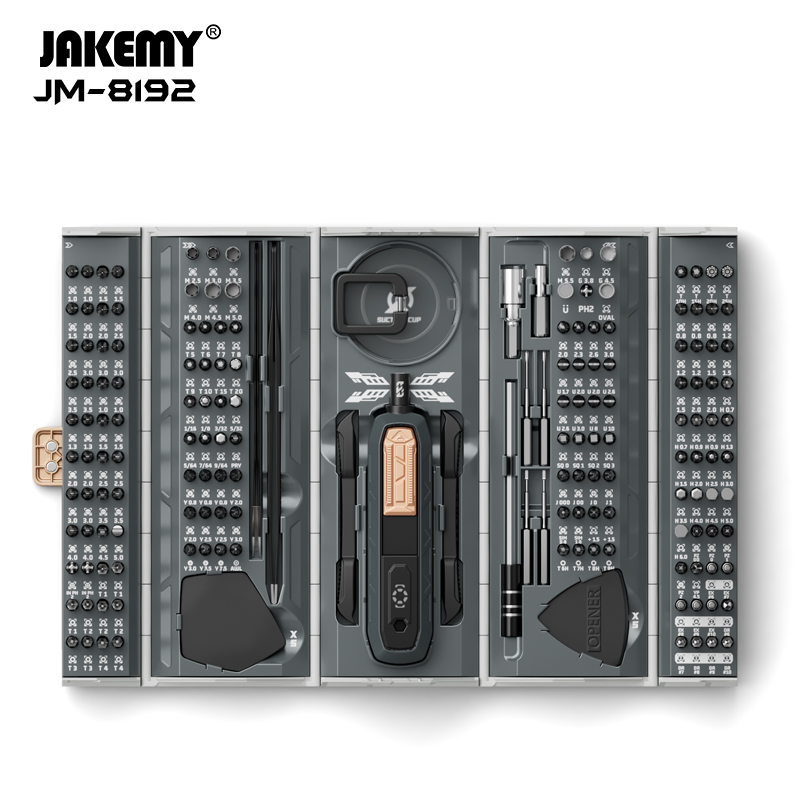

We not only supply screwdrivers at competitive prices but also support OEM & ODM screwdriver services to satisfy your specific requirements. Driven by innovation and trends, our screwdriver is the most popular product globally. Our wholesale screwdriver kits and other electronic repair tools are exported to more than 70 countries, including Europe, South America, Asia, and the Middle East.

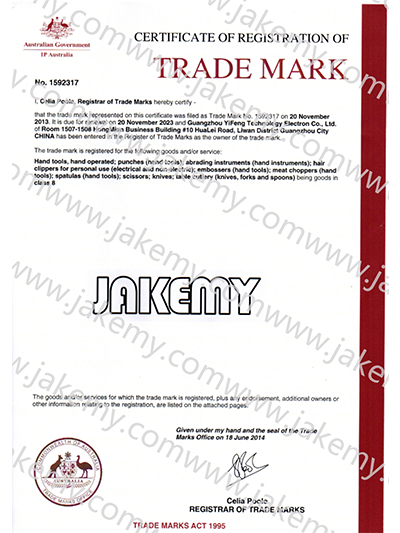

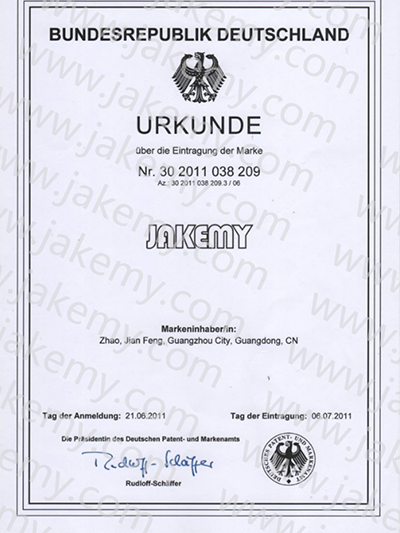

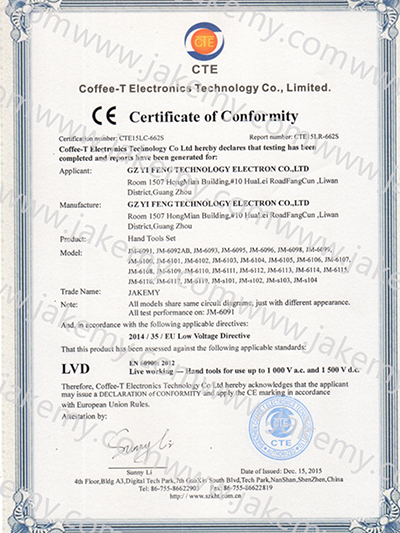

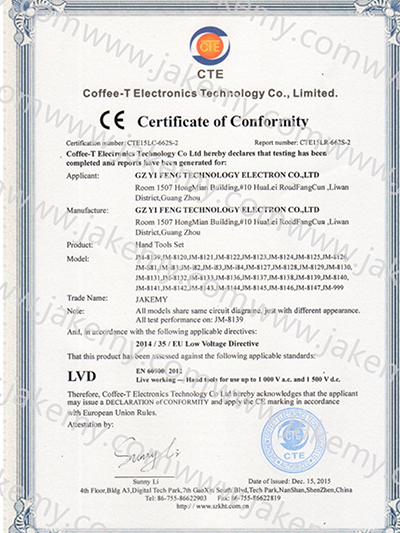

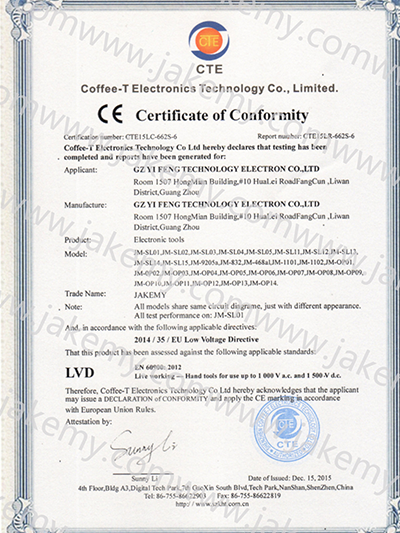

Jakemy has been awarded BSCI certification, CCC certification, RoHS certification, and CE certification, manufacturing high-quality screwdrivers for global brands. Additionally, working with international brands, we have accumulated a lot of experience from design to after-sale. Choose Jakemy, we will provide you with better services and one-stop screwdriver custom solutions.

Why choose Jakemy

Innovative Screwdriver

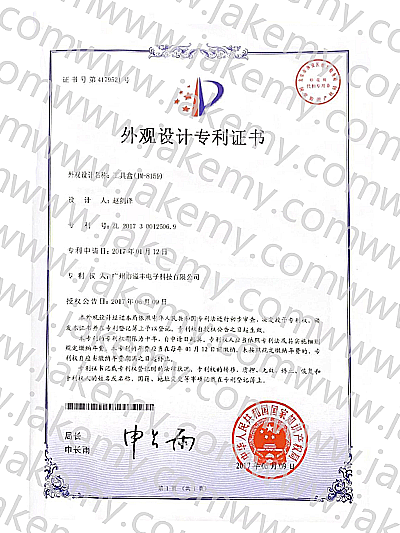

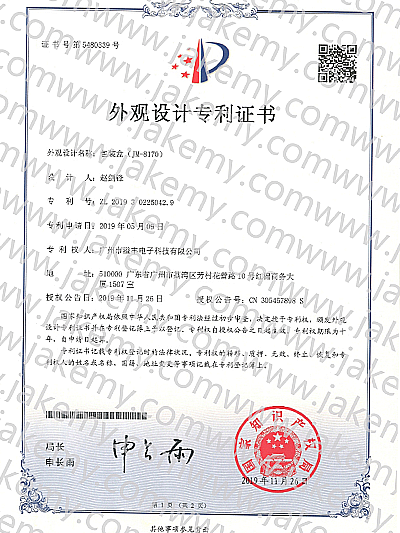

Jakemy has an R&D team to manufacture some popular and innovative screwdriver types based on market research and trends, like element, color, application, and design. While pursuing innovation, we are close to end consumers, exploring how screwdrivers are applied and what is the most popular screwdrivers in the market. Jakemy keeps on screwdriver innovation with more than 60 patents. Thus, we can act as your reliable screwdriver manufacturer to help you stand out in the industry.

Quick Delivery

To improve efficiency and quality, we have established 6 production lines and 20 advanced machines to manufacture screwdrivers, covering mold manufacturing, injection molding, printing, hardware manufacturing, screwdriver bits manufacturing, and assembly process. At Jakemy, our lead time can be as fast as 72 hours, and OEM & ODM lead time is generally 7-20 days. If you require a big order in a shorter time, you can find professional screwdriver manufacturer Jakemy to help you.

OUR SERVICES

We provide OEM/ODM services and accept customized orders. From on-demand design service to full product production, we will strive to meet all of your needs by providing you with qualified service support.

Professional Team

With more than 20 years of experience, Jakemy has specialized in screwdrivers and other electronics repair tools for global partners. No matter whether cross-border trade or e-commerce business, screwdriver design, or full production, we will strive to meet your needs with our better service. Our sales and customer service teams are available to respond to your inquiries within 12 hours. Plus, our warehousing service can last up to 60 days, with a large capacity of 8 million sets.

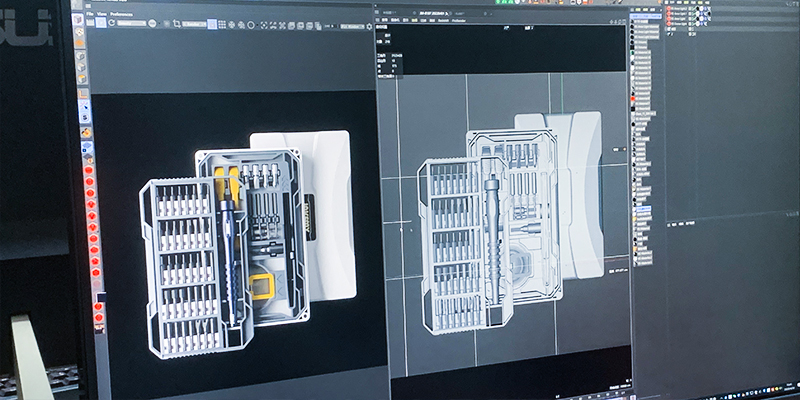

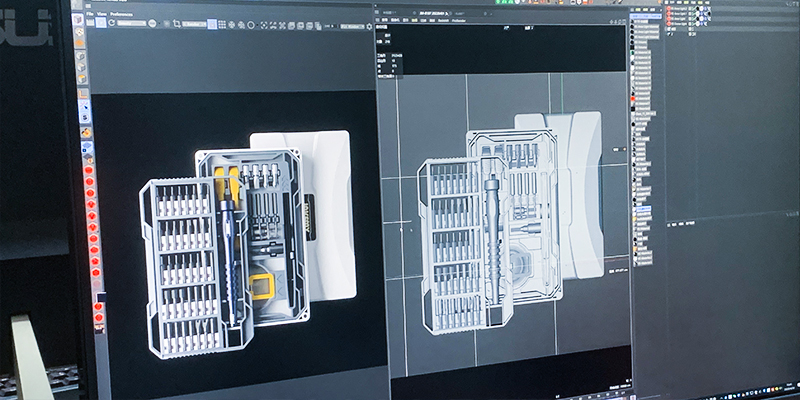

OUR R&D

Our prioprietary R&D team conducts yearlong, extensive market and product research. At the same time, new products are launched every year to ensure the constant innovation of our product lines.

OUR FACTORY

New products are manufactured every day throughout the many production lines of our independent factory. We employ a variety of high-quality raw materials to ensure the highest production efficiency and quality of our products.

OUR SERVICES

We provide OEM/ODM services and accept customized orders. From on-demand design service to full product production, we will strive to meet all of your needs by providing you with qualified service support.

OUR SUPPORT

Our sales and customer service teams are available to respond to your inquiries within 24 hours. We look forward to put our decade-long experience in this industry to your service at any time.

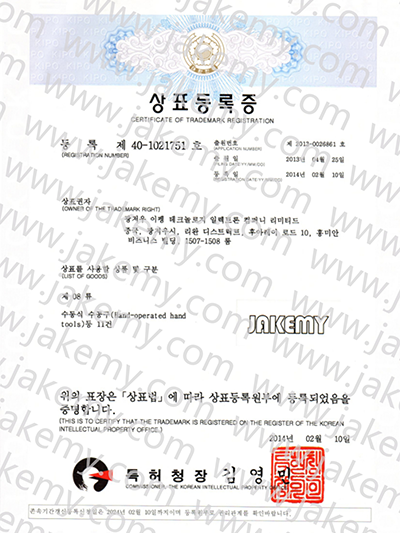

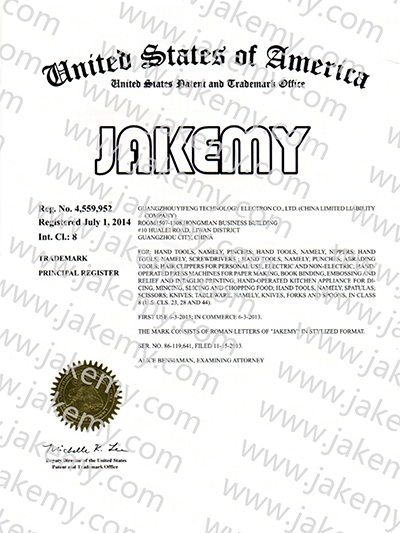

Certification

─────

The Latest News

Contact Us

Let Us Know How We Can Help

Fill up the form and our Team will get back to you within 24 hours.

Wanke Li Hardware Factory No.1 Huanzhen East Road, Yanbu, Dali Town, Nanhai District, Foshan City, Guangdong Province, China